We are V Notch Die Blades manufacturers in India. A V-notch die blade cuts V-shaped tracks in materials using high-speed steel or carbide. It’s used with a press or cutting machine in manufacturing.

V-notch die blade has a sharp V-shaped edge that cuts through the material to create precise V-shaped cuts.

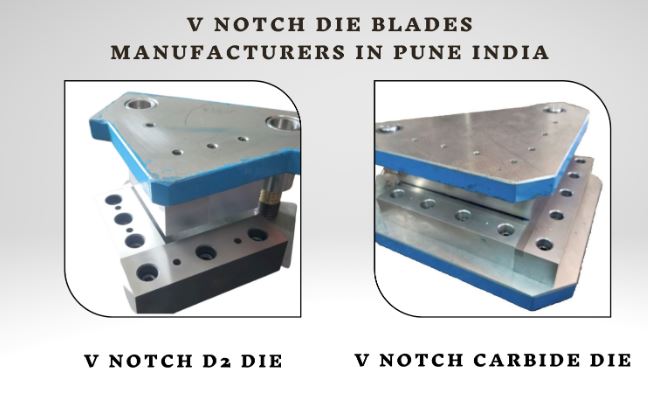

Types of V-Notch Die Blades:

1.Single V-Notch Die Blades:

Feature a single V-shaped cutting edge.

Suitable for applications demanding simple V-shaped cuts.

2. Double V-Notch Die Blades:

Possess V-shaped gaps on both edges.

Ideal for applications where dual V-shaped cuts or increased precision are necessary.

3. Variable Angle V-Notch Die Blades:

Allow for adjustments to the V-notch angle.

Suited for applications where flexibility in cutting angles is required.

4. Serrate V-Notch Die Blades:

Feature serrations along the V-notch.

Enhance gripping and cutting capabilities, suitable for materials prone to slipping.

5. Custom Profile V-Notch Die Blades:

Tailored to specific cutting profiles.

Ideal for unique applications or industries with specialized cutting requirements.

Benefits of V-Notch Die Blades:

1.Precision Cutting:

V-notch design enables precise cutting profiles, suitable for applications demanding accuracy.

2. Enhanced Shearing Action:

V-notch geometry enhances shearing action, resulting in clean and controlled cuts.

3. Reduced Friction and Heat Generation:

V-notch design minimizes friction, reducing heat generation during cutting for improved blade and material longevity.

4. Versatility Across Materials:

Proficient at cutting various materials, from metals to plastics, showcasing versatility in different industrial applications.

5. Reduced Deformation:

Minimizes material deformation during cutting, preserving the original shape of the workpiece.

6. Effective Chip Control:

V-notch configuration facilitates efficient chip control, preventing material build-up and ensuring consistent cutting performance.

7. Extended Tool Life:

Precision engineering, reduced friction, and heat contribute to an extended tool life, minimizing downtime for blade replacements.

8. Adaptability to Cutting Depths:

Designed to accommodate various cutting depths, providing flexibility in applications with diverse depth requirements.

9. High-Quality Surface Finish:

Clean and controlled cutting action results in a high-quality surface finish on the cut material, crucial for applications where appearance matters.

Applications of V-Notch Die Blades:

1.Metal Stamping:

Used for cutting and shaping metal sheets with precision.

2. Die-Cutting:

Employed in die-cutting operations for intricate patterns and shapes.

3. Metal Fabrication:

Integral in metal fabrication processes, including cutting and shaping structural components.

4. Automotive Industry:

Utilized in the production of automotive parts, ensuring exact cuts and shapes.

5. Textile Industry:

Applied in the textile industry for cutting fabrics with accuracy.

6. Plastics Industry:

Suitable for cutting and shaping plastic materials in manufacturing processes.

7. General Metalworking:

Widely used across various metalworking applications where precision cutting is paramount.

At NIKKY TOOLS, V-notch die blades stand as versatile tools offering precise cutting solutions across a spectrum of materials and applications. From achieving complicated designs to providing clean cuts, these blades play a crucial role in elevating the efficiency and quality of cutting processes in various industries.