We are a Shearing blade manufacturer In India. shearing blades play a crucial role and are instrumental in cutting through various metals with accuracy and speed, shaping the foundation of countless industries. In this blog post, we will explore the artistry and functionality behind shearing blades, shedding light on their features, applications, and the impact they have on the manufacturing landscape.

Shearing blades come in various types, each designed to meet specific cutting requirements based on the materials, thicknesses, and applications involved. Here are some common types of shearing blades:

1.Razor Blade Shear:

Ideal for thin sheet metal and light-gauge materials.

2. Straight Blade Shear:

Suitable for a wide range of materials and thicknesses.

3. Guillotine Shear Blade:

Widely used for cutting sheet metal and plates.

4. Circular Shear Blade:

Ideal for continuous cutting of long sheets or rolls.

5. Rotary Shear Blade:

Suitable for continuous cutting of coil or strip material.

6. Serrated Blade Shear:

Effective for cutting tough or hardened materials.

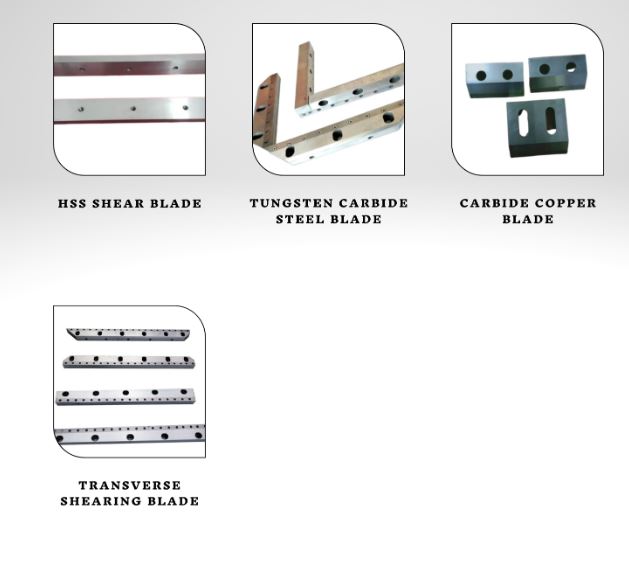

7. Tungsten Carbide Tipped Blade:

Suited for cutting abrasive or tough materials.

8. Variable Rake Shear Blade:

Ideal for cutting materials of varying thicknesses.

9. High-Speed Steel (HSS) Blade:

Commonly used for high-speed cutting applications.

10. Precision Ground Shear Blade:

Required for applications demanding high precision.

Applications of Shearing Blades:

1. Metal Fabrication: Shearing blades find extensive use in metal fabrication shops for cutting metal sheets to the desired size and shape. Whether it’s creating components for machinery or shaping structural elements, shearing blades deliver precision and efficiency.

2. Automotive Industry: In the automotive sector, shearing blades play a vital role in the production of sheet metal components for vehicle bodies, frames, and other parts. The accuracy of shearing is essential for maintaining the structural integrity and quality of automotive components.

3. Construction: Shearing blades are employed in the construction industry for cutting metal sheets used in the fabrication of structural elements, roofing materials, and other components required for building projects.

4. Packaging: Precision cuts are crucial in the packaging industry, where shearing blades are used to cut and shape metal sheets for the production of containers, cans, and other packaging materials.

At NIKKY TOOLS,Shering blades impact resounds across diverse industries, shaping the raw materials that form the backbone of modern manufacturing. As technology continues to advance, shearing blades will remain at the forefront of innovation, contributing to the evolution of metalworking processes and ensuring the continued efficiency and accuracy in metal cutting applications.