We are a CRGO Metal cutting tools manufacturer In India. CRGO (Cold-Rolled Grain-Oriented) metal cutting tools stand out as the artisans behind the creation of transformer cores. In this blog post, we delve into the significance of CRGO metal cutting tools, exploring their features, applications, and the transformative impact they have on the production of high-performance transformers.

Key Features of CRGO Metal Cutting Tools:

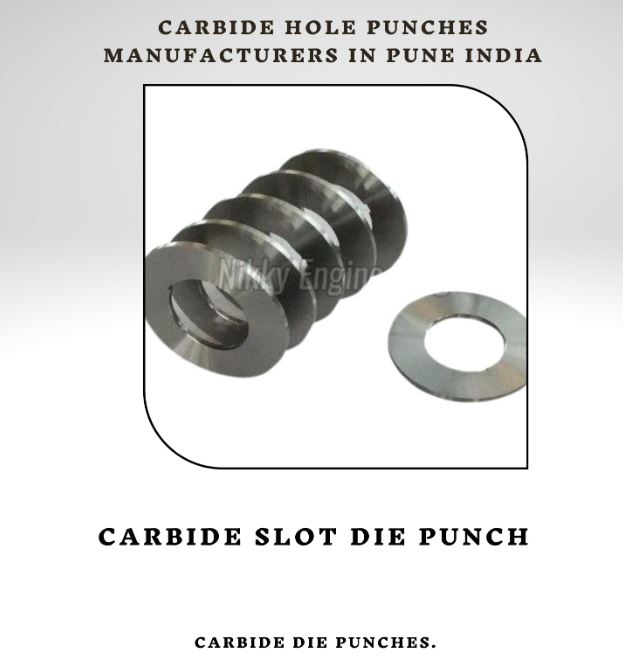

1. Material Compatibility: CRGO metal cutting tools are specifically crafted to handle the challenges posed by Cold-Rolled Grain-Oriented Steel. The tools are constructed from high-speed steel (HSS) or tungsten carbide to ensure durability and maintain sharpness during the cutting process.

2. Precision Machining: The cutting edges of CRGO metal cutting tools undergo meticulous machining to achieve sharpness and consistency. This precision is paramount for creating clean and accurate cuts in the CRGO laminations, preventing burrs, and ensuring the uniformity of the transformer core.

3. Customized Designs: The design of CRGO metal cutting tools is tailored to meet the unique requirements of transformer manufacturing. From slitting cutters to rotary shears, these tools come in various forms to handle different stages of the laminating process.

4. Heat Resistance: CRGO metal cutting tools are designed to withstand the heat generated during the cutting process. This heat resistance is crucial to prevent tool degradation and maintain cutting efficiency over prolonged usage.

Applications of CRGO Metal Cutting Tools:

1. Lamination Cutting: The primary application of CRGO metal cutting tools is in the precise cutting of laminations from CRGO steel sheets. These laminations form the core of transformers and are crucial for optimizing magnetic properties and minimizing energy losses.

2. Transformer Core Manufacturing: CRGO metal cutting tools are instrumental in the production of transformer cores used in power distribution systems, electrical appliances, and industrial machinery. The precision of these tools directly influences the efficiency and performance of transformers.

3. Customized Designs: Manufacturers utilize CRGO metal cutting tools to create custom designs and shapes for transformer cores, meeting specific requirements for different applications, industries, and transformer types.

4. High-Volume Production: CRGO metal cutting tools are designed for efficiency in high-volume production settings, ensuring consistent and precise cutting across a large number of laminations.

CRGO metal cutting tools play a critical role in the intricate dance of transformer manufacturing. As transformers continue to be integral components of our electrical infrastructure, the precision and efficiency offered by CRGO metal-cutting tools become increasingly essential.